Refractories dried shapes

It is the most delicate step of refractories production process.

It is the most delicate step of refractories production process.Sanac has completely automated this operation to ensure the quality consistency of the various mixtures.

Depending on the type of product

the binder may be organic or inorganic. It gives cohesion to the mix required for forming.

Through an appropriate predetermined thermal cycle

Through an appropriate predetermined thermal cycle the binder carries out its action allowing the movement and handling of the product.

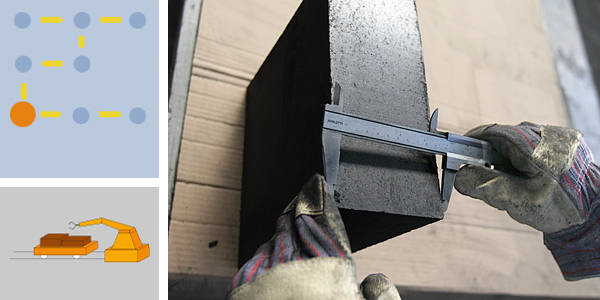

Bricks

Bricks coming out of the oven after heat treatment are classified and checked in order to verify the dimensional characteristics size and the external appearance.

To preserve their integrity during storage and handling,

the products are placed on pallets and packaged according to the specific needs of each customer.